Watch video online

Our service and customer service

Those who know our equipment and have seen previous designs will appreciate this technical solution. Thanks to special silicon reinforced hoses we get high quality products. They are easy to dismantle, they are very soft. Here, you see, I’m twisting them now. At the same time they are certified, they have a European certificate and we install them in our encapsulator. We us two tanks in our encapsulator. One is for the oil or fish oil that you want to fill in the capsule. The gel is in the other similar 18 liter tank. The system in the lid is designed in such a way that a continuous supply of gel or encapsulation material is provided to our tanks throughout the entire 24 hour operation of the equipment. It is worth mentioning the quality of this tank. It fully complies with GMP requirements. It has a semicircular bottom and a radius, which allow cleaning and washing these tanks inside and outside. Those who have seen our previous tanks will be agreeably surprised by the progress we have made in this respect. We have also made convenient side handles for removing and placing tanks filled with the gel and material up into our encapsulator. This is also very convenient and we have fulfilled the request of our clients to make this process as convenient as possible. Once again I will demonstrate how the gel is fed from our heating tank, from our container with a stirrer to the equipment. Please note that two hoses go out, one goes to the tank and one from the same tank it returns to our reactor. Here are the connections.

Also, please note that on the back side we have made a complete protection from contact with the hot material of the water bath, that is, we have insulated it and made a protective stainless steel panel. On the back side there is a compressor system and a transport oil cooling system it is covered with a protective closure for safety. Perforated holes allow air circulation to cool and maintain a certain temperature at the pumps and other equipment, which is located in the backside. The electrical cabinet is also made of stainless steel, inside which all our electronic devices are located. I’d like to highlight that all components are made in Germany. Frequency controllers, various electronic components meet high requirements of the European equipment market. CAPSULESFORYOU.COM invites you to our showroom where we can demonstrate the operation of our equipment. We are always happy to see you. We are open to everyone and will be happy to show you how our equipment works. You are welcome to contact us at any time.

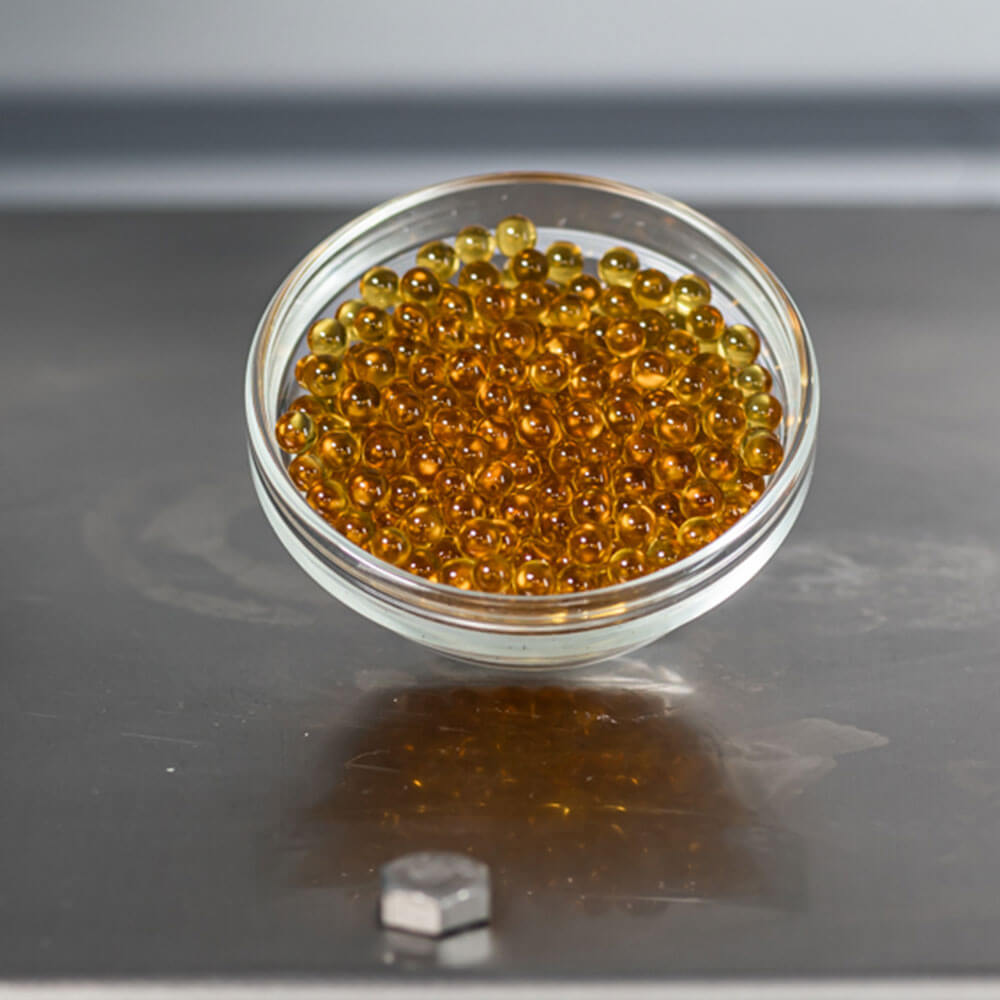

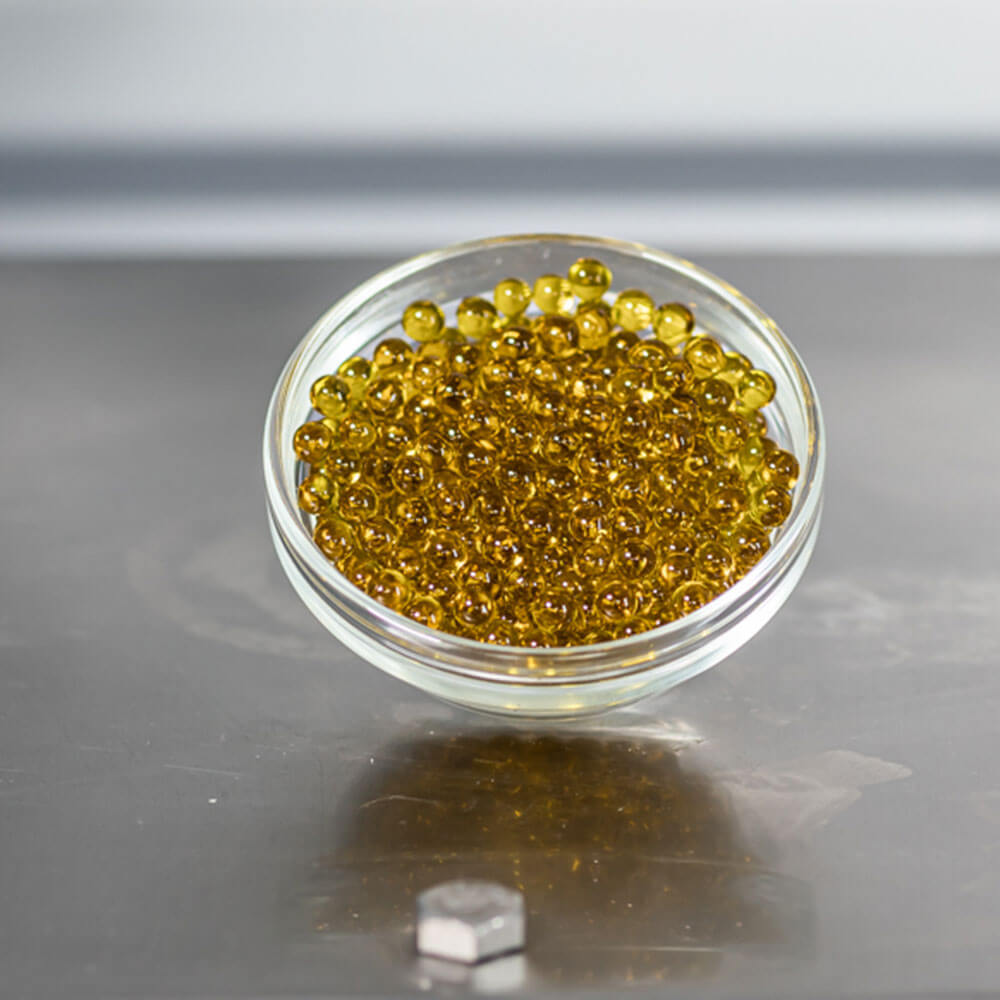

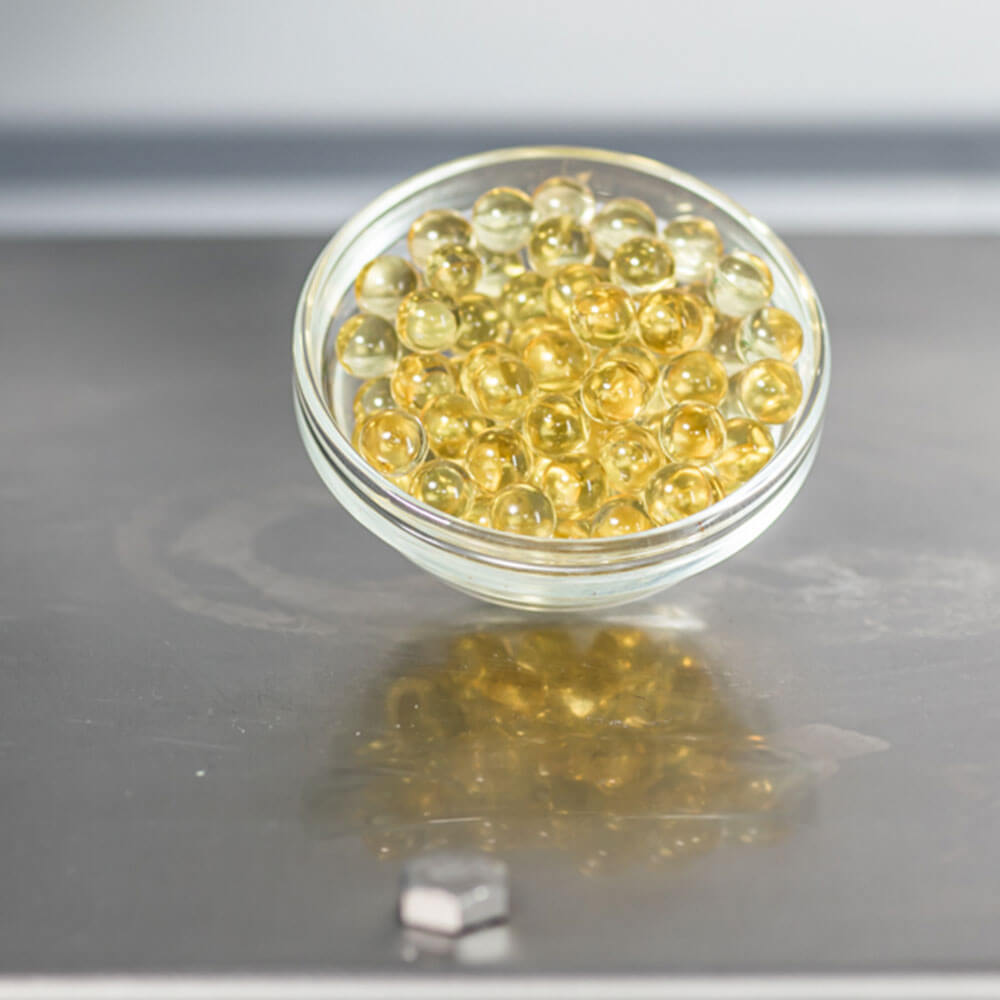

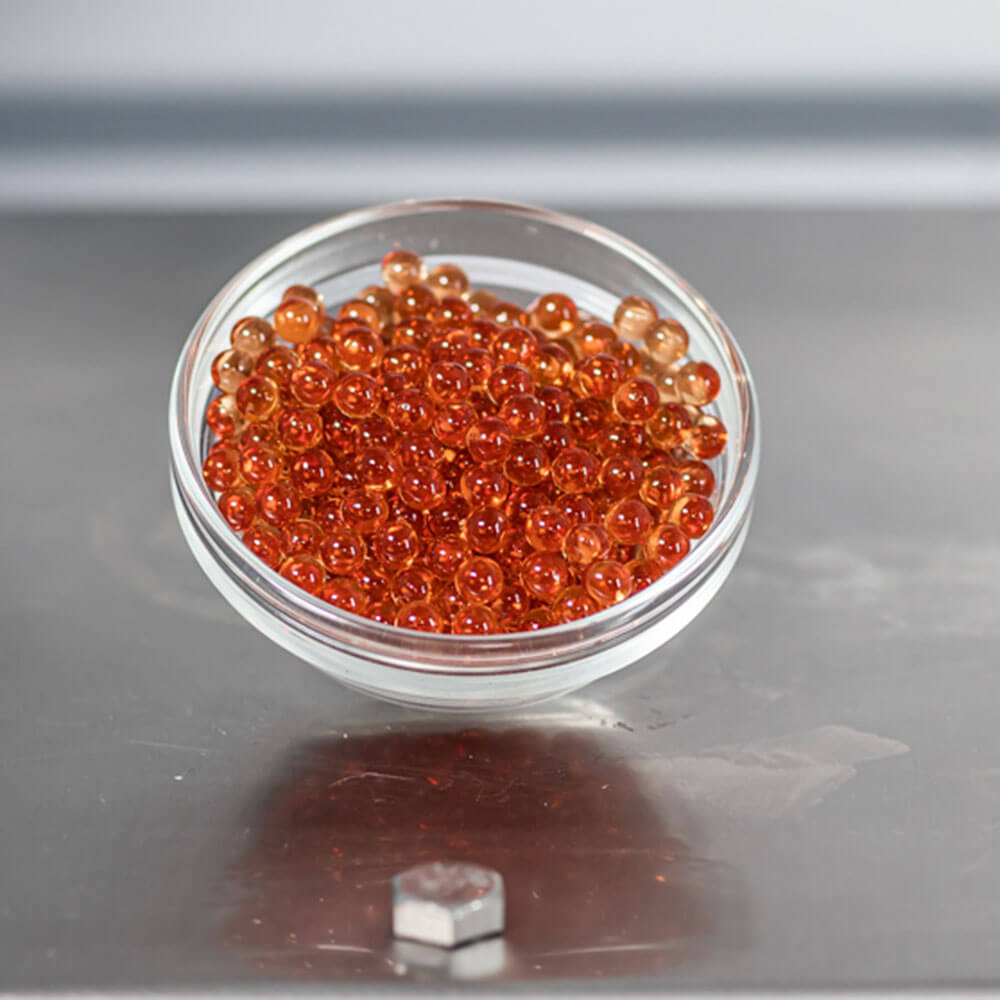

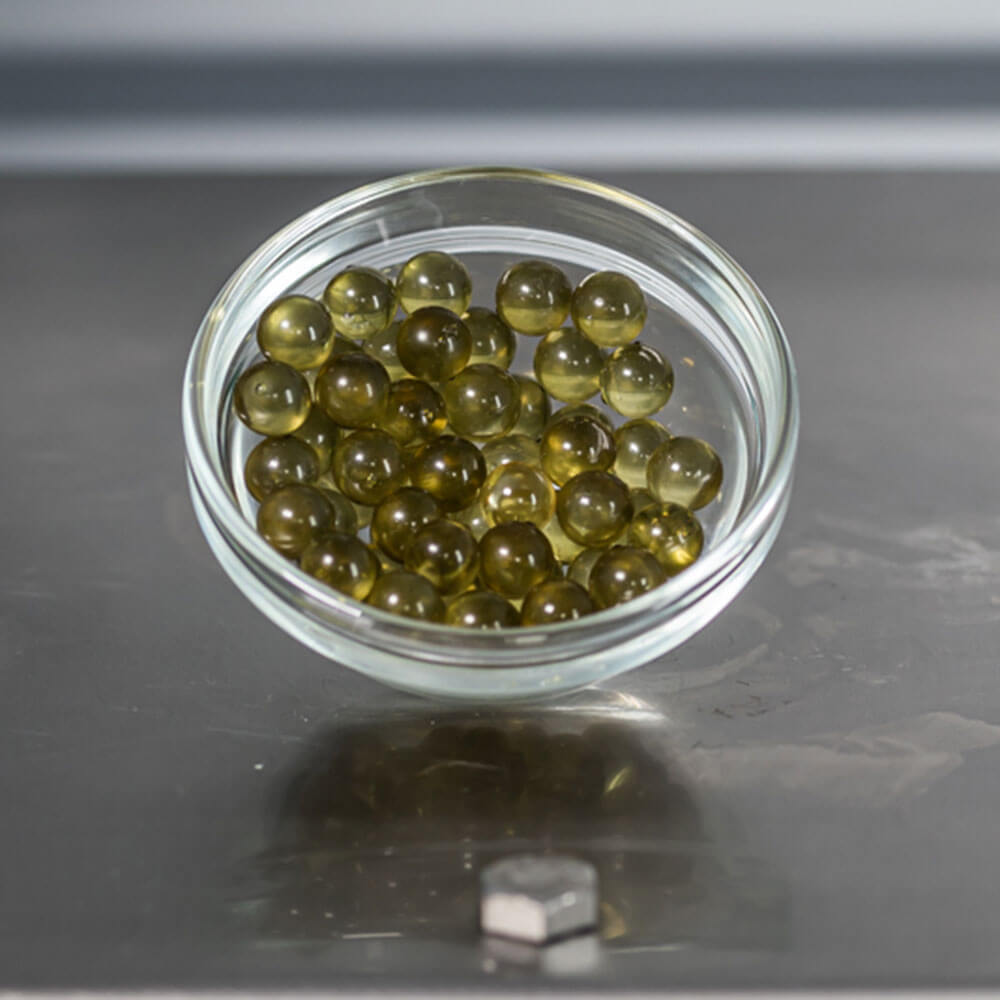

Our company offers equipment and technologies for encapsulating oils and various fats. These are vegetable oils that you see on the shelves in pharmacies. Behind my back is a new automated capsule production line using seamless technology. Our technology provides a capacity of about 90,000 capsules per hour. At present, no other company offers such equipment or technology. We have also developed a new shell of a plant matter called Agar-Agar. This is an alga-based powder which we use to make vegetarian capsule shells with remarkable characteristics. Our capsules have a round shape only, they are seamless, which ensures an undeniable advantage over technologies existing on the market. We do not have any residuals or rejected products, there is no need to dispose production waste, since all raw materials used in our technology is used to produce capsules. Behind me is a new automated encapsulation line with a capacity of 90,000 capsules per hour. This high speed can’t be provided by any other equipment.

Our line consists of several machines. The first machine is a special reactor where agar or gelatin gel is produced. The gel is made at a temperature of about plus 90 degrees Celsius. The gel is fed through the heated hoses to our encapsulator by a special pump. Capsules are formed from the gel and oil in the encapsulator. Then the capsules go out for washing and drying. This is a boiler, a heated tank with an agitator that makes the gel, there is also a pump, a system of heated hoses, the encapsulator itself, as well as a centrifuge for hydroextraction and washing of capsules after encapsulation. Our company has been producing encapsulator for 20 years and until today, our equipment was, let’s say, in the affordable price segment. And today we are ready to present you a completely updated design of the encapsulator made of stainless steel that meets all GMP requirements. All edges, all internal edges are made with a radius, which provides convenient use and guarantees the quality of washing.

Our equipment operates at the highest possible speed. We have added special high-precision pumps that regulate the dosage of capsules and operational stability of the equipment. Commissioning and adjustment time has been significantly reduced. In addition to the high-precision pumps installed in our new encapsulator that maintain a stable pressure of all liquids, as well as an accurate dosage of capsules, all electronic components such as motors, pumps, gearboxes have parts made in Europe: Germany and Italy. This ensures excellent quality and non-stop operation around the clock. We strive to make our products as reliable and pleasant for our customers as possible. If we compare the old model and the new one, we will see that everything has been significantly changed. It is difficult to assess the difference visually, although the appearance has become much more presentable. The transport oil cooling system has also been completely updated. We have shifted from dipping the cooling elements into the oil. Now we use a special container with a double bottom which the refrigerant passes through.

In addition to the technology, we have developed an automated encapsulation line that allows producing these products. Our automated line consists of the following types of devices: a heated tank with an agitator for producing both gelatin and Agar gel. This is a universal unit. This tank has mixing blades that allow maintaining homogenous condition of the gel during its production. The volume of this heated tank with agitator is 50 liters, thus ensuring continuous 24-hour operation of the equipment. A special pump feeds the jail from the heated tank with agitator to our encapsulator via a special heated hose. These hoses maintain heating up to +90 degrees Celsius, thus ensuring equal heating of the entire material and continuous operation of the equipment. Behind me is a new model of the encapsulator entirely made in accordance with GMP standards.

All the inside and outside edges are made with a radius allowing easy and efficient cleaning. Also, all electronic, electrical components, pumps and electric motors are of European production from Italy and Germany. We strive to create a device that is as reliable and convenient for our users as possible. After the capsules are formed they are automatically released into the washing and spinning device, which significantly reduces the operating time in comparison with our old model, where this operation was performed manually. Now the capsules automatically jump from one device to another, which eliminates the need for manual operator work. We have also developed a unique system for continuous drying of capsules. It is different from all those options that exist on today’s market of pharmaceutical equipment. This system has no analogues and we do not show it today only for the reason that we do not want our competitors to copy it before we start its production and sale. We have developed our automated line, which is entirely made of stainless steel, ensuring compliance with the GMP standard requirements. You can easily certify and validate such equipment at your production facility, and use it to manufacture products of the same quality as the market leaders. Our compact automatic line is a unique offer. Today, there is no analog equipment on the capsule market, in terms of either cost or performance, or uniqueness of the shell composition and material. We are the only company that has achieved it. We ship our equipment to any country, including the former Soviet Union countries, the US, Canada, Europe and around the world. We have well-working delivery channels and friendly companies that will help us with customs clearance in your country. At any time, our specialists will come to you and tell you how to arrange the capsules production business in the best way. This automatic line allows switching from the gelatin shell to Agar-Agar shell of the capsule and in the reverse direction. This allows you to produce more unique types of products. I am very proud of the result that we have achieved together with my team. Behind my back are the years of research, the work of our designers and process engineers.

Technical specifications

Now I will tell you about the design features of the GMP encapsulator. Now I will tell you about the design features of the GMP Hemp oil encapsulator. Now I will tell you about the design features of the GMP Hemp oil encapsulator. The top panel has a control system. There are temperature controls for transport oil, gel, and oil that is placed inside the capsule. There are temperature controls for transport oil, gel, and hemp oil that is placed inside the capsule.There are temperature controls for transport oil, gel, and hemp oil that is placed inside the capsule. Now the ambient temperature is shown, but when we program our encapsulator to work, we set the temperatures we want to work with. If your material, oil or animal fat, requires heating our tanks, which are located at the back of the encapsulator, also have a water jacket system, a water bath, which will warm up the materials. If your hemp oil requires heating our tanks, which are located at the back of the encapsulator, also have a water jacket system, a water bath, which will warm up the materials. If your hemp oil requires heating our tanks, which are located at the back of the encapsulator, also have a water jacket system, a water bath, which will warm up the materials. Now we use high-precision controls that allow adjusting the speed of material movement within our system. It means that special pumps regulate the feeding rate of the material that becomes the capsule shell and the material that is placed inside the capsules. This significantly enhances the dosing accuracy. Having set certain indicators on the devices today, you can run it in the same mode the next day and reproduce it all. In order to see the encapsulator operation process and the formation of the capsules we use special stroboscopic lamps that show us what happens when we form capsules thanks to their light pulsation. The capsules move at a very high speed, more than 24 capsules per second and they seem invisible, but when we turn on the stroboscope, it gives us the opportunity to see how the capsules are formed. Now the capsule production is not in process, I’m just showing you how it works. Now the hemp oil capsule production is not in process, I’m just showing you how it works. Now the Hemp oil softgels production is not in process, I’m just showing you how it works. You can also switch the lighting mode of the internal camera to see the entire process. Later we will make a video clip showing the equipment in operation.

The encapsulator itself is fully manufactured by our employees and our workers at the production facility in Minsk, Belarus. We carefully test each machine before sending it to customers, thus guaranteeing, workability of this equipment for 200%. Same as before, any of our customers have the opportunity to invite our Adjuster to visit their facility. Within 5 days, he will commission and set up the equipment, train the personnel and give some advice and recommendations on how to use the equipment. By the present time, none of our customers has stopped the capsules production for any reason. Our equipment works everywhere, people produce the products and successfully develop their business.

Additional information

I will make a short presentation of our line in order to tell you about each unit and each part of the equipment in our automatic line. This is a heated tank with agitator in which we prepare the gel. Now I am pointing at an electric motor with blades installed inside, the motor is mixing the volume of gel that we are preparing with the blades. This heated tank with agitator has a water jacket and thermal protection, which helps to maintain the temperature so as not to heat the air in the room. The system of observation windows, lighting system. From our tank, the gel is pumped through special heating hoses to the tank in the encapsulator and through the return hose is returned back to our tank. This is done in order to maintain the high temperature of the gel inside our reactor at all times. We work with Agar-Agar that requires a temperature of more than plus 90 degrees Celsius. If there were only one heated hose, then the material inside would cool down and block the gel from moving. Therefore, we lift the material into the tank of the encapsulator using one hose and dump the excess gel back into our boiler via the second hose. This electric cabinet regulates the heating temperature of our heated hoses, it also regulates the speed of the gel feeding to our tank at the top and the device that regulates the temperature of the gel that we made, as well as the speed of the blades rotation. Everything gets into our encapsulator through heated hoses. Here is the GMP version of our encapsulator, made entirely of stainless steels.

All corners are rounded, ensuring easy cleaning and washing in accordance with GMP standards. Sealing of our chamber eliminates the ingress of all kinds of polluting particles. There is a thermal insulation material inside the chamber. It maintains a certain temperature. Now I will tell you about the design features of the GMP encapsulator. The top panel has a control system. There are temperature controls for transport oil, gel, and oil that is placed inside the capsule. Now the ambient temperature is shown, but when we program our encapsulator to work, we set the temperatures we want to work with. If your material, oil or animal fat, requires heating our tanks, which are located at the back of the encapsulator, also have a water jacket system, a water bath, which will warm up the materials. Now we use high-precision controls that allow adjusting the speed of material movement within our system. It means that special pumps regulate the feeding rate of the material that becomes the capsule shell and the material that is placed inside the capsules. This significantly enhances the dosing accuracy. Having set certain indicators on the devices today, you can run it in the same mode the next day and reproduce it all. In order to see the encapsulator operation process and the formation of the capsules we use special stroboscopic lamps that show us what happens when we form capsules thanks to their light pulsation.

The capsules move at a very high speed, more than 24 capsules per second and they seem invisible, but when we turn on the stroboscope, it gives us the opportunity to see how the capsules are formed. Now the capsule production is not in process, I’m just showing you how it works. You can also switch the lighting mode of the internal camera to see the entire process. Later we will make a video clip showing the equipment in operation. Rounded corners provide easy cleaning, which meets the GMP standard. Stainless steel is inside and outside. This material is suitable for the production of food and pharmaceutical products. You can easily obtain any permit to use this equipment at your facility. The bottom part of the chamber is for the transport oil cooling system. Inside there is a special box with a double wall, where the coolant is pumped by a pump and all the transport oil is cooled in this box. If necessary, this unit can be easily detached, drained, and cleaned inside. The inner corners of this box are also radial, which makes them easy to wash. I have just shown you the design of this container for transport oil cooling. I am holding a similar container. This is a double-walled, stainless-steel container with radial corners, in which the coolant is fed along the inner walls. And here is the transport oil. It’s intensive cooling takes place here.

Customer Testimonials

Wow this is pretty cool, is it possible to get more information? Michael Heller, Ph.D (Linkedin)

Has any vendor actually purchased one in USA that can verify the machine and quality? Marc Normandeau (Linkedin)

How small of a ball can the machine make? Andy Klein (Linkedin)

What are some of the benefits agar has over gelatine based capsules ? Jay Carnahan (Linkedin)

Very informative and interesting in the field of development and mfg of Softgels particularly transparent ones. Indeed great information for research and business development for future. Regards to both Mr Roman and Professor Borisov. Shivkumar Dalchand Kesharwani (Linkedin)

Better would be to have or produce the oil yourselves and make the product from A to Z. Also you can control the conzentrations better. Would make more sense to me if i wanted to make such a healthy product. Rudi Gerlach (Linkedin)

Please DM me the presentation, and thank you for putting this together. Stephen DuBose (Linkedin)

Exciting technology! Najela Scott (Linkedin)

This video shows exactly why we need regulation in the industry. Kevin Gallagher (Linkedin)

Hello Roman, l have a customer in New Zealand. Can l sell your machine to them? Jusu Kim (Linkedin)

Interesting, I would like to explore the possibilities to collaborate together. I’m going to sending you DM for more information. Carlos Javier Rivera (Charles) (Linkedin)

I want to order the Basic machine to make CBD gel caps and delivered to 6329 State Road 54, New Port Richey, FL 34653 USA. Thank you. Garry Dhaliwal, M (Linkedin)

I know it’s a crazy, difficult time right now, and we’re all trying to keep our heads above water. I wanted to reach out to you because we have great experience and results in working within the Cannabis and CBD industry. Our system helps businesses like yours fill up their pipeline with potential clients without having to leave the comfort of your home by using Facebook/Instagram Ads. Robert Rivera (Linkedin)

Hi Roman! We are a custom stainless fabrication shop and I saw that you use custom built reactors in your process. I was curious who makes your tanks and mixers for your encapsulation solution? Troy Hanchey (Linkedin)

Hello Roman, we got a new facility set up, not sure if we will be making any big purchases yet. But I wanted to get some more info from you. Once we have the machine, what sort of ingredients/supplies will we need besides the CBD oil. Michael Hammer (Linkedin)

Hello Roman, you came up as a suggestion with whom LinkedIn thinks I should connect with. I’m happy because I work in the CBD industry extensively now and thought we may be able to find some networking opportunities. Dan Licitra – LIONs™ CBD and Hemp Payment Solutions (Linkedin)